How Many hp?

When you buy a 100 horsepower compressor, how many horsepower do you think it should consume? Yes, this is a trick question.

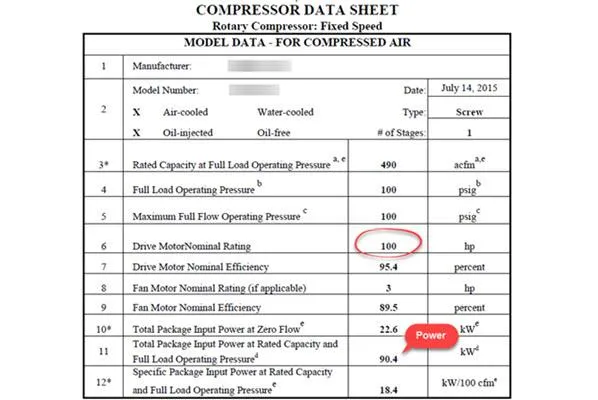

Compressor ratings are often confusing when it comes to checking the specifications of screw compressors. The 100 hp associated with the Compressed Air and Gas Institute (CAGI) compressor data sheet shown in this post refers to the nominal rating, not the actual compressor power consumption. If we remember back to technical school we will remember that one horsepower equals 746 watts. So the expectation would be that a 100 hp compressor would consume 74.6 kW at full load and full pressure.

Looking at the actual rating we can see this compressor consumes far more than this, 90.2 kW or the equivalent to over 121 hp. Why is this?

One of the reasons is this compressor is an air cooled compressor. It has electric powered cooling fans that consume extra power over and above the nominal rating. This adds to the total.

In addition to this the main compressor motor is only 95.4 percent efficient and the 100 hp refers to the motor shaft output. Therefore, for rated shaft output this motor needs to consume about 105 hp.

But the biggest reason relates to the service factor of the motor. Electric motors have a service factor rating that allows the motor to be run higher than its rated nameplate amps. More amps means more power input.

Why do the manufacturer’s push into the service factor? Because you the customer purchase based on numbers. Given the choice of Compressor A that produces 400 cfm or compressor B that produces 490 cfm the customer will often choose the bigger number. The further into the service factor you go, the more flow a compressor can produce. But, if the customer simply compares compressors based on nominal hp, they may miss the fact that the compressor with the highest flow may consume much more power and actually be less efficient, increasing the operating costs. This is why it pays to check the CAGI sheets.

Why should you care? Well, motors that are pushed into the service factor are often less efficient and have a shorter life. Typically motors loaded to 80% of motor rating are at the most efficient point of operation. And wire size can be an issue, if the input wiring to a compressor is sized for nominal power the wire capacity may be on the edge of acceptable, causing extra power loss due to overloading.

Sometimes the solution is to oversize the motor, if this is an option or purchase a compressor with a higher pressure rating than where it will be running. This will keep the motor loading low and be easier on the compressor on the whole.

Next time you choose a compressor, have a close look at its operating characteristics so you can make a wise choice.

Learn more at our training: www.compressedairchallenge.org/calendar