High Discharge Pressure

An automotive manufacturer was having trouble with their large centrifugal compressors constantly going into surge condition. This is a damaging condition where the air going through the compressor suddenly stops and starts, shocking the fast spinning rotors in the machines and causing stress on the internal components.

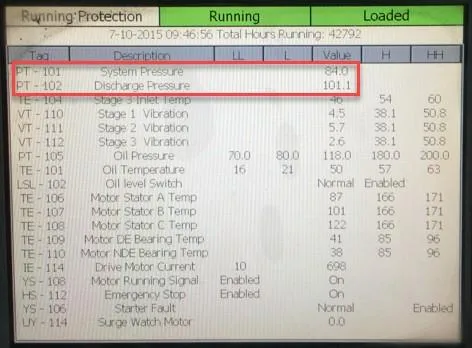

Data logging was done and found that while the output pressure from the compressor room was normal, about 80 psi, the discharge pressure of the compressors was sometimes very high running between about 100 and 110 psi. Something in the compressor room was causing a major pressure restriction.

An investigation was initiated and found that the piping in the room was more than adequate in size for the flow and, because the compressors were lubricant free, there were no system filters being used. The only remaining components between the compressor discharge and the compressor room output was a number of parallel connected refrigerated air dryers. Measurements were taken and, sure enough, there was a pressure differential of up to 30 psi across the dryers.

The investigation showed that one of the dryers was not passing any air. Some others showed signs of flow restriction as well. The cause of the problem became obvious when the dryer condensate drains were operated only to find that a hailstorm of ice pellets was ejected. The evaporator control of the dryers had been adjusted too cold, the dryers were freezing up, causing internal ice blockages. Some readjustment was required to get things back to normal.

Learn more about air dryers in our next Compressed Air Challenge seminar in your area. Visit www.compressedairchallenge.org for more information.