Forgotten Dryer Setting

A food processing plant purchased an energy saving externally heated purge type dryer to save compressed air system energy. This dryer is designed to consume only 7.5 percent purge flow, compared to 15 percent for a standard heatless dryer, and was purchased with an onboard energy management system (EMS). The internal dewpoint dependent switching system is designed to detect the moisture content of the air and turn off the wasteful dryer purge when it was producing dew point levels lower its rated -40 level. On dryers that are loaded at less than the rated capacity, and experiencing cool and dry ambient conditions, this saves quite a bit of energy. The dryer in question was loaded to about 20 percent flow when all things were considered.

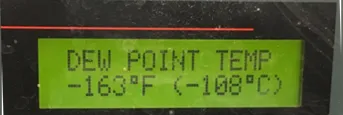

A compressed air auditor was called in to do an assessment of the plant. During his data collection phase the auditor noticed the dryer was producing air at -163?F. A quick check showed that the internal energy management system had been turned off for some reason. Rather than consuming 7.5 percent purge about 20 percent of the time due to the low load, the dryer was continuously purging non-stop on a 24 x 7 basis. Because of this, the dryer was unnecessarily consuming about 38 percent of the compressor's average compressed air output, plus its 4 kW rated heater power, equivalent to about $9,000 per year in extra operating costs.

The dryer is designed so that the energy management setting is internal to the control, not an external switch that is obvious to operators, so the status of the EMS setting can easily forgotten. A few quick pushes of buttons had the dryer back to normal, saving energy again. The auditor noted that this was the third dryer he had checked in the last three months that had this problem. The auditor recommended that the operators regularly monitor the dew point display and take action if extremely low values are observed.

Learn more about dryers at our training: www.compressedairchallenge.org/calendar